Our PRODUCTS -- CFW Automation Sendirian Berhad

Resistance Temperature Detectors

What is Resistance Temperature Detector (RTD)?

Generally, electrical resistance of any metallic conductor varies according to temperature changes. The sensor for measurement of temperature by utilizing this phenomenon is called "Resistance Thermometer" or "RTD" and can measure temperatures more precisely than temperature sensors.

Its Features

Resistance temperature detectors for industrial applications have the following features.

- Good sensitivity

- Excellent stability and reproducibility

- High accuracy

Structure and Measuring Methods

Structure:

Metal wire that changes its electric resistance to changes in temperature are utilized is called "Resistance Wire". This resistance wire, normally of platinum, is used to manufacture a temperature sensor called "Resistance Temperature Detector (RTD) Element". Generally speaking, RTD is composed of RTD element, lead wire, protection tube and terminals.

Measurement Methods:

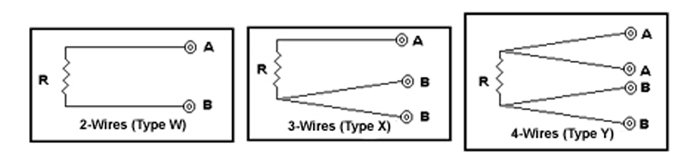

2-Wires Connection : Type W

RTD element is connected to respective two wire leads. Although it is less expensive than other types, it is not recommendable for high precision measurement of temperature because it is susceptible to lead resistance and produces error.

3-Wires Connection: Type X

One end of RTD element is connected to two wire leads and the other end connected to single lead to eliminate the effect from lead resistance. This type is most widely used as a reliable method in industrial applications.

4-Wires Connection: Type Y

RTD element is connected to respective two wire leads to remove the effect from lead resistance. This connection cancels lead resistance effect and is especially recommendable for high precision measurement of temperature but somewhat expensive than others types.

Precautions in Practical Application

Selection of proper RTD suitable for the application is the most important factor. For precision measurement of temperature, consideration should be given to selection of RTD element, protection tube, structure and fitting (location) according to the respective resistance to heat, corrosion, mechanical shock and other environmental conditions.

R = RTD Element

A or B = Code for Terminal

- = Lead Wire